Gear pumps are among the most widely used groups of hydraulic pumps, which are divided into two main groups, internal pumps and external pumps, which can be used according to the type of needs in any industry. The main movement in these pumps is not reciprocating, but the rotation that causes work to be done in these pumps. The function of the hydraulic gear pump is in such a way that inside it two gears are involved, one of them is called the idler wheel and the other one is called the driving wheel. Whenever the gears move, the teeth are spaced apart, and in this way, by creating suction, the fluid is drawn into the teeth and then passes through the teeth and moves towards the pump outlet valve. Sealing between the teeth of the pump does not allow the oil to open to the inlet valve and will necessarily move to the outlet of the pump.

The hydraulic gear pump is included in the group of positive displacement pumps; In these types of pumps, a certain volume of fluid passes through the pump with each rotation of the teeth. Considering that gear pumps are able to cover a wide range of flow rate and working pressure, they are considered the most widely used group of hydraulic pumps; In addition, due to the price of these pumps, their use is also suitable for making hydraulic units.

Types of hydraulic pumps

- External hydraulic gear pump

- Internal hydraulic gear pump

External gear pumps

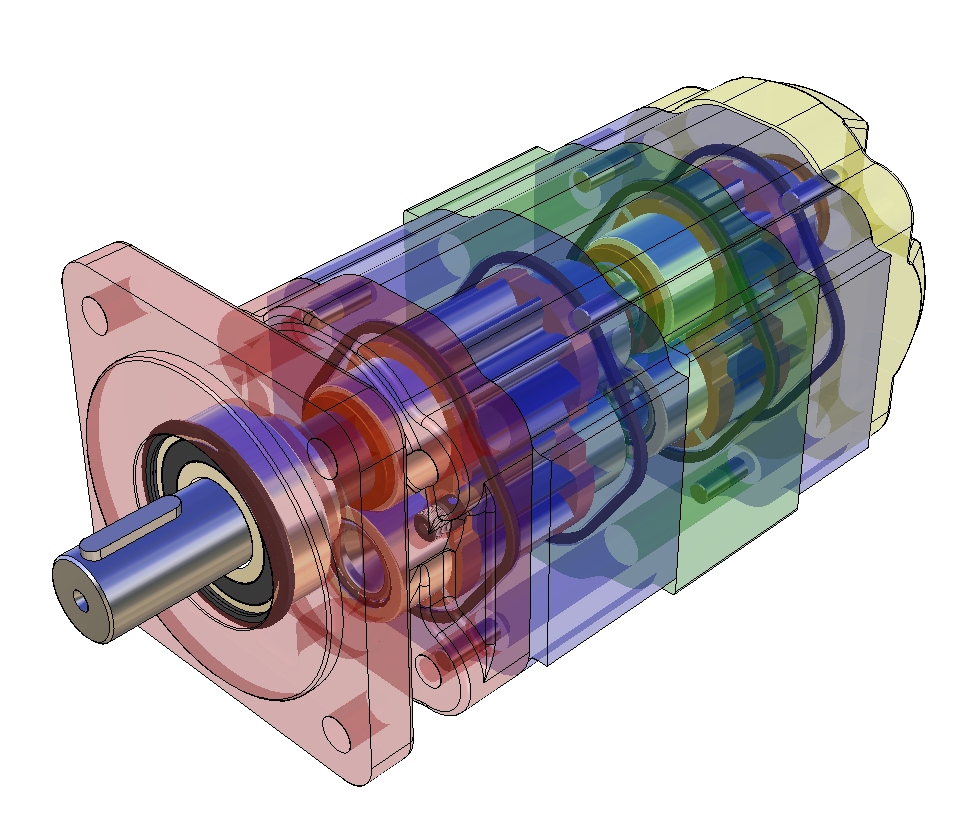

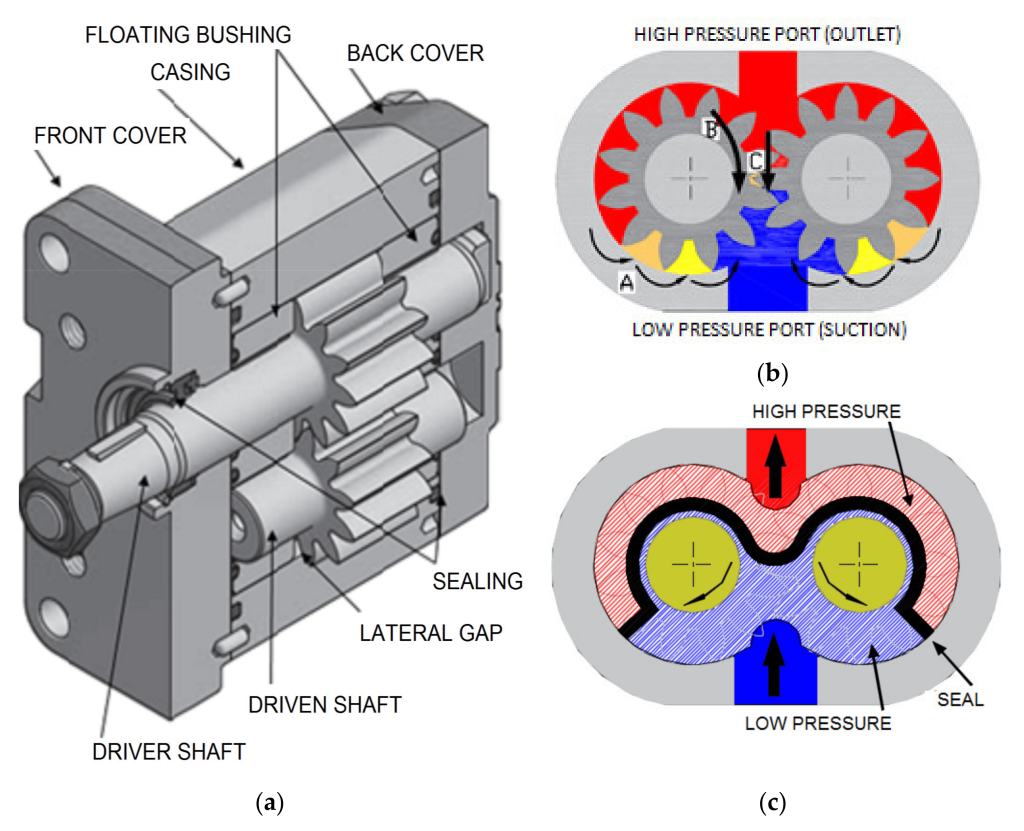

In hydraulic external gear pump, one of the gears is rotated by the drive system and the other gear also rotates. The space between the teeth, shell and side plates create a flow of oil. In the area where the teeth are out of engagement and the volume of the chamber increases, a negative pressure is created in the suction line and it continues to increase. In this way, the fluid in the tank enters the suction line under atmospheric pressure and fills the space between the teeth.

In this area and because of the internal seal, the oil is sent to the high-pressure outlet. It seems very important to pay attention to equipping the leakage seal in the hydraulic gear pump

The reasons for the widespread use of external gear pumps in hydraulic systems are as follows:

- Creating a relatively high pressure due to the small volume

- cheap price

- Wide range of

- Wide temperature and viscosity range

- rotation speed

In hydraulic external gear pump, we are faced with two different types:

- one axis

- Two axis

This division is a subset of simple or helical gears. The helical type is mainly used in cases where we want a smoother flow than the simple gear and we also need a higher capacity of the gear pump. Although even a simple gear produces smooth and even flow. Usually, the small type of these pumps work at a speed between 1750 rpm and 3450 rpm and in the large type of pump up to 650 rpm.

The external gear pump is more effective than other types of hydraulic gear pump groups. The hydraulic external gear pump has a small tolerance and the main shaft is supported on both sides. This makes its pumping capacity up to 200 BAR/3000psi, which makes the external gear pump suitable for hydraulic use.

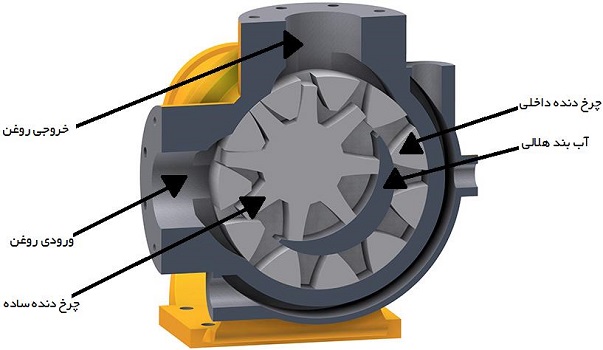

Internal hydraulic gear pump (moon and star hydraulic pump)

In general, internal gear pumps are widely used in hydraulic systems due to their compact dimensions and relatively cheap prices. Internal gear pumps are an example of hydraulic gear pumps, which are sometimes known as moon and star pumps.

The use of internal hydraulic gear pump or moon and star pump is mostly for lubrication and feeding at working pressures less than 1000 psi, but multi-stage types of these pumps provide the possibility of working at pressures of 4000 psi.

By looking at the figure in front of the building, we can see how the internal gear pump works, which includes an internal gear, a simple gear, a crescent-shaped seal, and an outer shell. With the rotation of the gears, due to power transmission, it causes the fluid to be sucked from the tank and the oil is directed around the crescent seal. engage each other, the fluid will be pushed towards the outlet of the pump.

How the internal hydraulic gear pump works

Application of hydraulic gear pump

Internal and external gear pumps are widely used in industry and road construction machines for power transmission as well as material transmission. Among its other uses, the following can be mentioned:

- Pressure supply in

- petrochemical industries

- Power supply in military industries

- Road construction, agricultural and construction machines for power transmission and lubrication

- Transfer of industrial oils

- Transporting some fuels with specific concentrations

- Power transmission in the food and beverage industry

- Polymer and textile industries

- Automotive industry

- Production of industrial molds

- Plastic injection machines

Advantages of hydraulic gear pump

The use of hydraulic gear pumps is very common due to their quality and reasonable price. Among the advantages of these pumps, the following can be mentioned :

- power transfer

- supply pressure

- Transfer of high pressure industrial oils

- Smooth and quiet operation compared to other hydraulic pumps

- High durability and longevity

- The possibility of easy coupling with industrial electric motors

- The good price

- High Quality

- Smooth operation